当前位置:

YUDAO hot runner production adopts standard professional management throughout the whole process. Each process has been carefully designed and standardized by the engineering department, equipped with professional technicians to ensure that the production quality of each process is not inferior to our standard. The company has advanced fluid polishing machine, multiple precision production equipments, also with a production base of tens of thousands of square meters. It provides a solid backing for the creation of excellent molding products. YUDAO hot runner makes injection molding more perfect, by strictly controlling product quality assures that each perfect finished product delivered to your hand finally.

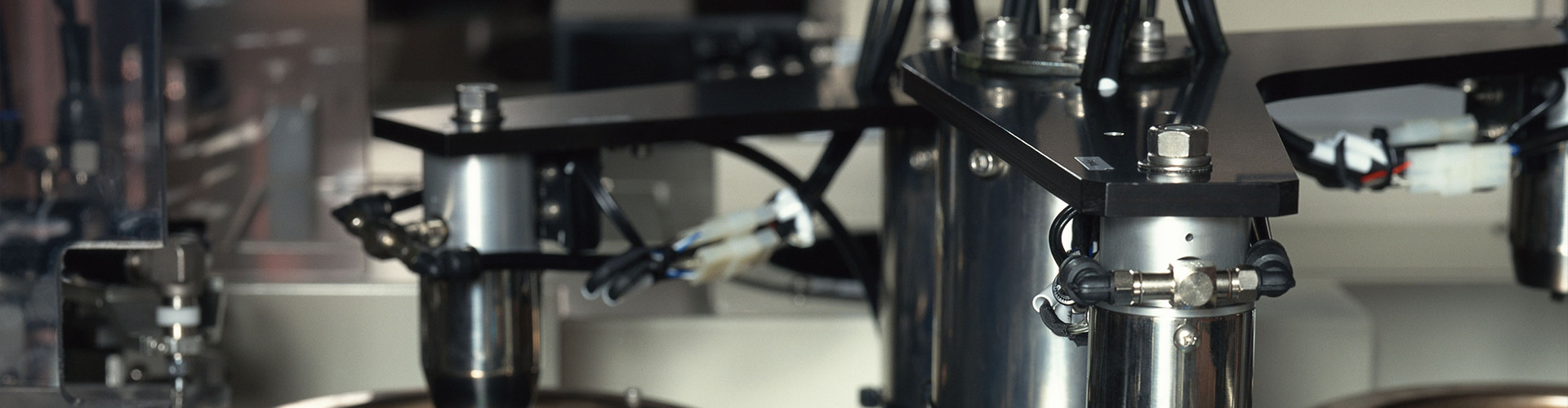

Defects are not allowed in the testing process. Efficiency and safety start from the testing step. And the professional attitude of the staff is cultivated, and the pursuit of quality is endless. For each hot runner, from raw materials to finished products, is a quality marathon checkpoint. We strive for excellence in 24 meticulous processes. As an old brand enterprise, YUDAO hot runner has accumulated 20 years'experience in hot runner industry. In project development, it is a real project quality-oriented and customer value-oriented company. With the continuous improvement of customer's internal decoration of products and the demand for various components, “YUDAO” hot runner adopts special process processing to solve the customer's worries and make product quality become an enterprise Market competitiveness.

YUDAO hot runner attaches great importance to the development and integration of human resources. It not only gathers a group of highly creative designers, but also concentrates on professional and sophisticated personnel in the face of complex projects to provide customers with the best solutions. With a more comprehensive way of thinking is really a demand-driven design, a more responsible design team, a strong and customer-oriented strategy, and the ability to achieve the desired results. Professional mold flow analysis technology tests each functional component and optimizes it at the beginning of product design.